A shop drawing is the main strength of the steel fabrication industry. It is a drawing or a set of drawings usually made by the fabricator, manufacturer, contractor or supplier, too often by utilizing detailing services of detailers, under contract from the owner and their drawn version of information shown in the construction documents.

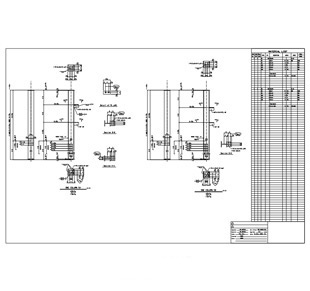

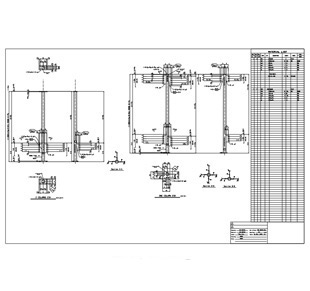

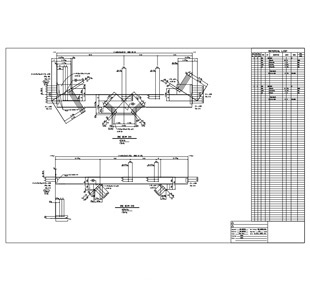

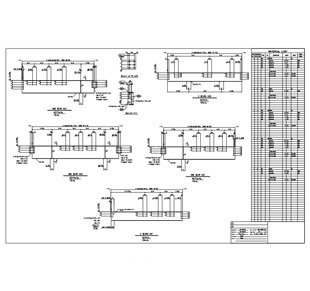

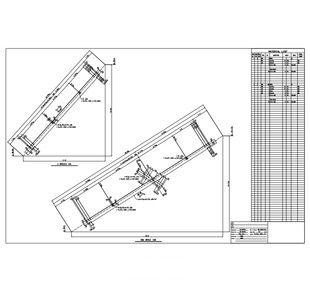

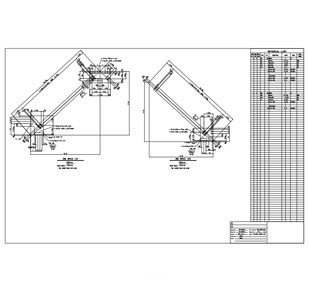

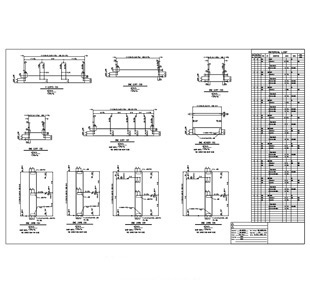

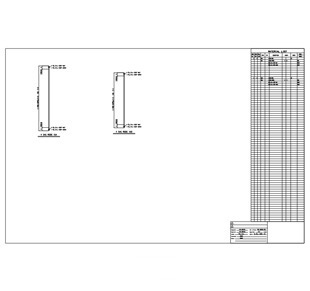

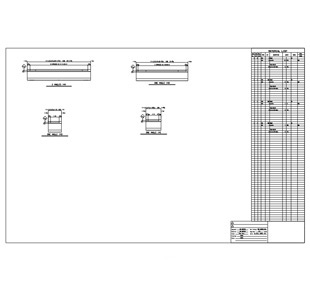

These drawings provide sections & views containing dimensions, welding/bolting information, the fabrication standards, details, and are created to simplify the process and steps of fabrication and erection to the fabrication teams and contractor's erection teams. These drawings serve as a guide to execute the fabrication perfectly. Well detailed Shop drawings helps in getting architectural approvals and can greatly influence the profitability of a project.

Features of steel fabrication shop drawings -

Shop drawings are typically required for fabricating different components.

Shop drawings are in addition to the contract drawings but with more details. They are like a step by step assembly manual.

Shop drawings contain more & complete details than the construction documents and are used to show essential and required information for fabrication & at times erection too.

The style of the shop drawing is different from that of the architect’s drawing as they primarily focus on just the particular item or erection.

Steel fabrication shop Drawings provide complete information of all components’ dimensions, fastening methods, design specifications & Bill of Material.

Shop drawings compulsorily include following -

Comparison information for the architect and engineer Shop drawing, besides being clear and complete, includes information for the engineer and architect who will be comparing and referring to the specifications and drawings. Shop drawing takes care of the appearance, performance, and specific descriptions in the specifications and construction drawings.

Changes or alterations from the construction documents Notes relating to any changes or differences from the original documents are also included in shop drawing for the architect’s and engineer’s approval to allow them to analyse any modifications.

Suggestions where verification of dimensions is needed from the jobsite When jobsite dimensions need to be verified as an actual dimension may vary from the one shown on the construction drawings. It is crucial that fabricated item when they arrive on the jobsite do not require any field modifications and are ready to be installed. Shop drawing hence should indicate ‘Approver please verify’ for accuracy. Approver measures and verifies dimensions, or else advises according to site conditions.

Steel fabrication drawing services are used for getting prepared -

Structural member detailed drawings of columns, beams, bracing, stair, Ladder, handrails, frame & truss etc.

Anchor setting plans & Embed layout plans.

Main & Miscellaneous steel erection drawings.

Data files needed for fabrication & documents that shows all pre-fabricated components thoroughly.

In today’s dynamic and fast-paced construction industry, fabricators are racing to complete their work as they are faced with tighter construction schedules and have longer material lead times. Nowadays, steel fabrication shop drawing can be taken care of with different types of advanced detailing software thus saving time and money.

A team that provides cost-effective and quality service definitely helps companies not only to bid profitably but to deliver quality service to customers. As the industry advances and competition increases, Structural steel fabrication drawing services will continue to play a very big & important role in the construction of building structures.